S.H.O.E.

Masters thesis

I am creating objects to do what they are designed not to do. Using the ubiquity of the shoe against itself, I am subverting the expectation of performance in footwear. While there are existing examples of this in sport, trades, and fashion; shoes which glide on ice using blades, those with spikes for climbing trees, stilts; I am probing the space of the everyday action. In his Crisis of the Object, Andre Breton talks of “revealing the marvelous in everyday life.” My work occupies the space between the surreal and the functional, defamiliarizing the everyday while narrowing the use case of the multi-use object. Furthermore, these objects are designed to perform their ultra-specific tasks at specific locations, and as such are made from materials bought and found in situ, and fabricated nearby. It is my intention to prompt the user to ask “what is a shoe and what can a shoe be?”

Shoe for leaning forward 17 - 22°

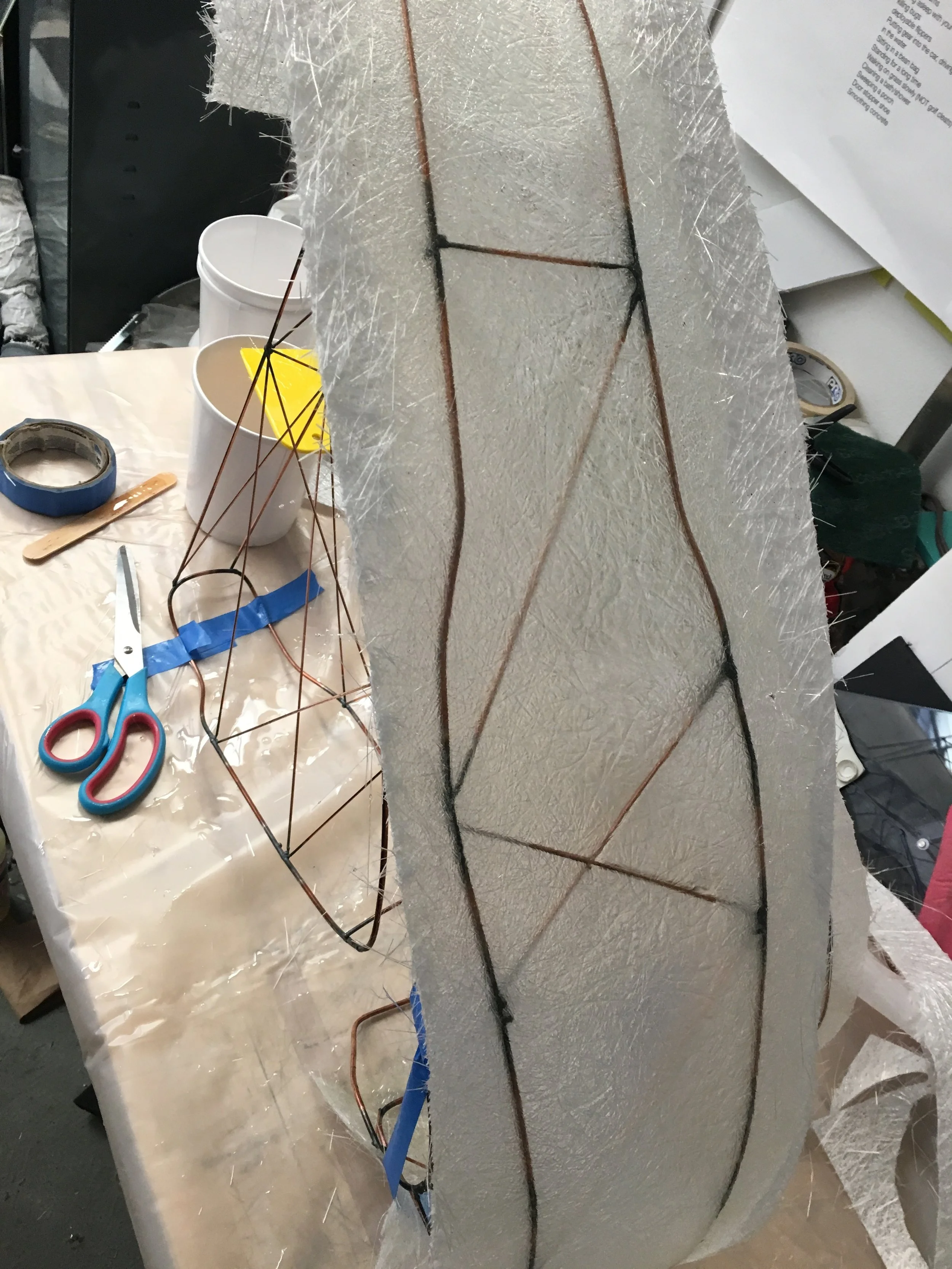

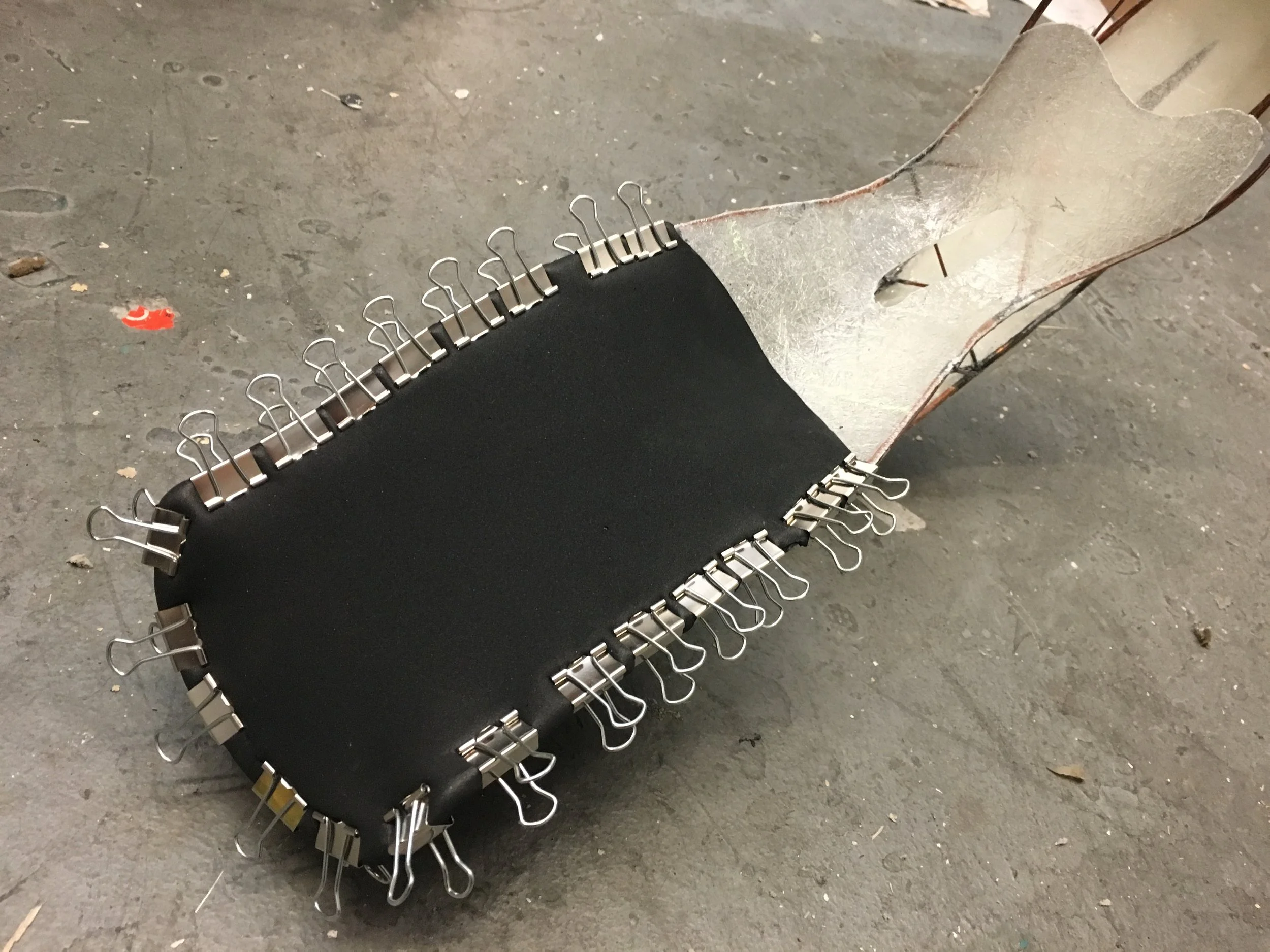

One of my eight deep explorations into the misuse of the shoe was the action of leaning forward while peering over a ledge or counter. I worked through many iterations of foam rough models before breaking down the granularity of the structure even further; using steel rod, neoprene, EVA foam, fiberglass, epoxy and convoluted foam.

Eight Key Moments

Using conversational, observational, and experiential studies, I identified eight specific moments in daily life of misuse of the common shoe. The everyday shoe is designed with walking, light running and standing as its use case. I identified those moments that we incorrectly use a shoe - and subsequently designed ultra-specific-use-case footwear optimized for those moments.

Survey of specialized shoes

I had to know what already existed in the world before I set out to create something new. My study ranged from prosthetics to fashion, to Scandinavian linemen pole climbing boot augmenters, and everything in between.

Prototypes

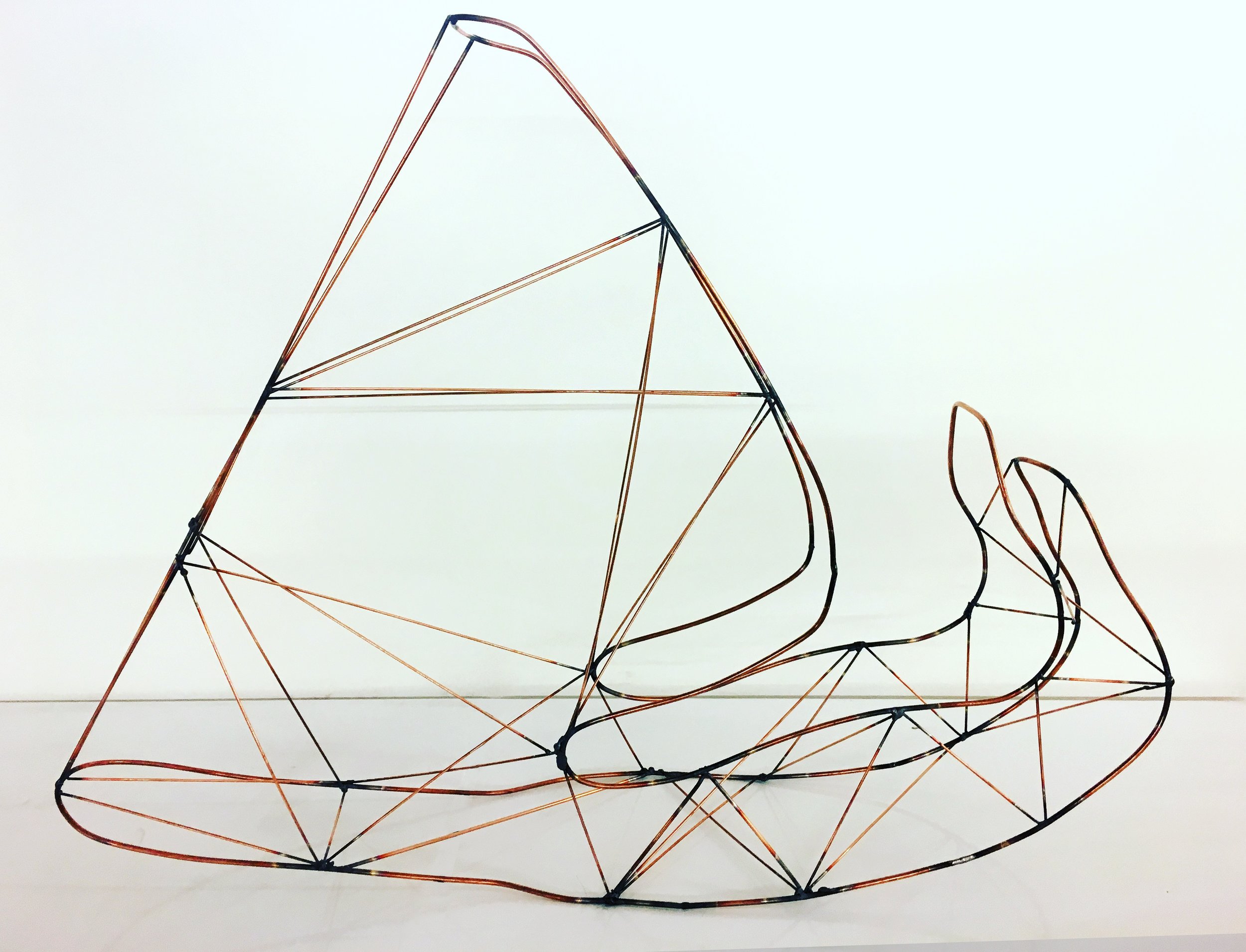

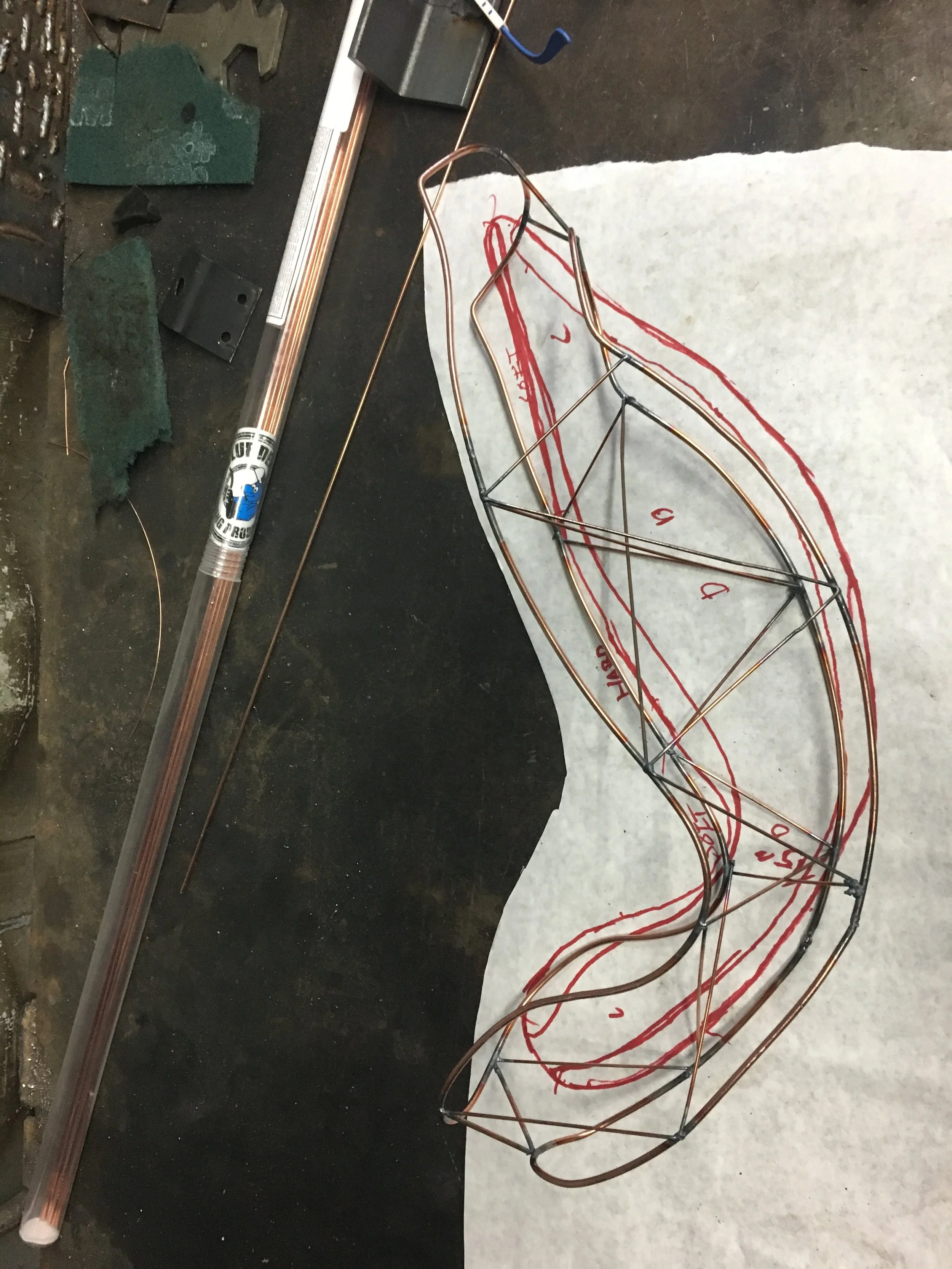

Granularity of Structure

I used a granular framework to break down the uses of the shoe. Continuing along that vein, I broke down the each shoe by the necessities of its elements. Triangulated steel rod was used for lightweight structure, two part foam for the midsole, vulcanized rubber for grip, neoprene slung around the structure for loose support, epoxy and fiberglass for rigidity, and convoluted open cell foam for comfort. These examples are three rough working prototypes of three ultra specific use case "shoes." The first is a shoe for leaning forward precisely 17-22 degrees. The second is a shoe for resting while waiting in a queue line. And the final prototype is a shoe for laying supine.

Building it wrong

I was never out to make a sneaker. This is about breaking the notion of the shoe, and as such I forced myself to look to manufacturing processes outside of the realm of a typical shoe. I TIG welded these triangulated structures and laminated epoxy fiberglass to them for further rigidity. Every time I was close to doing it the "right" way, I did the opposite.

Process

Workspace

The materials study process for this project was vast. By the end, I had experimented with over 40 different materials to achieve the desired sensations and use cases that I was after. Naturally, my workspace reflected this study and the heights of mounds of foams, glasses, beads, balls, and meshes would ebb and flow over the 9 month duration of the study.

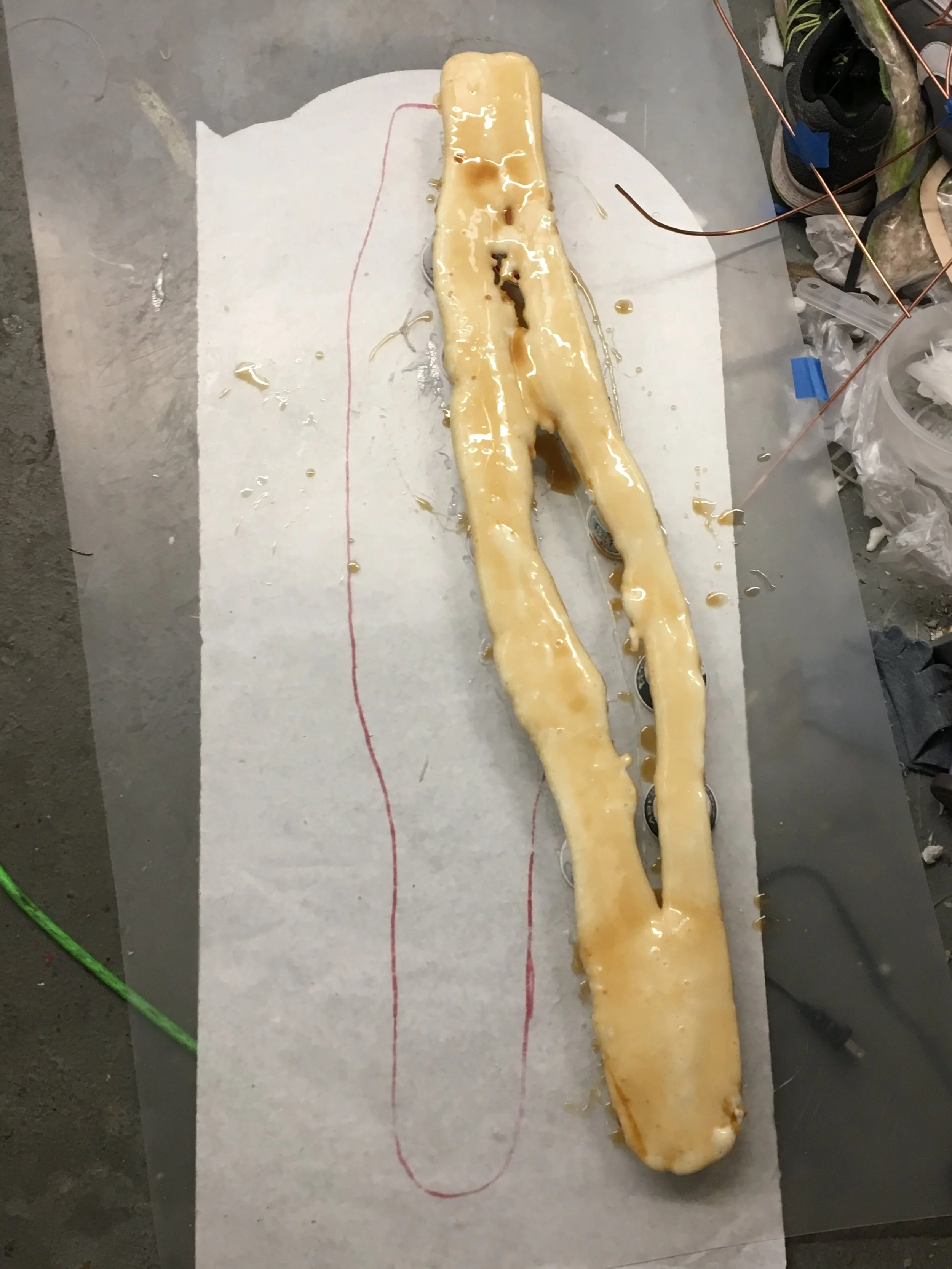

Process begets form

For the sole of the models I let gravity create texture. Using a jig to pour the liquid factory accurately, I would then flip the entire apparatus upside down. The drips that yielded gave the soles their grip. Each sole has the same shape but is unique in its texture.

Melding of Theory and function

This early prototype of a shoe for laying supine was influenced by the philosophy of Benjamin, Breton and Rancière - recontextualizing materials to attain the phantasmagoric, or dreamlike, object. This, and other prototypes like it, were assembled using materials and found objects. I was following a rich history of defamiliarizing the object to the user to expose the extraordinary in the every day.

last comes first

The last is used by shoe makers to form their materials around - a stand in for the users foot. These can be expensive and last a lifetime. I needed mine to be cheap and expendable. I wrapped duct tape around my foot and leg and slowly built up wall thickness. The bottom third is filled with sand, the top is full of repurposed bean bag filling.

Materials

I worked to utilize materials far from the norm of the shoe manufacturing industry. Here I am testing fiberglass rod from kite builders as a triangulated form, with RTV rubber impregnated with bean bag filling for a sole.

Surface to Human Object experience

The 9 month long investigation yielded more questions than solved problems, and, by my metrics, I'd call that a success. I encapsulated my work in a 90 page thesis book.